Load Cells and Their Types

Mastering the Art of Weighing: A Comprehensive Guide to Load Cells with loadcell.ae

Accurate weight measurement is the cornerstone of countless industries. From manufacturing and logistics to construction and agriculture, precision weighing is essential for efficiency, quality control, safety, and overall operational success. At the heart of these weighing systems lies a critical component: the load cell.

Understanding Load Cells: The Foundation of Accurate Weighing

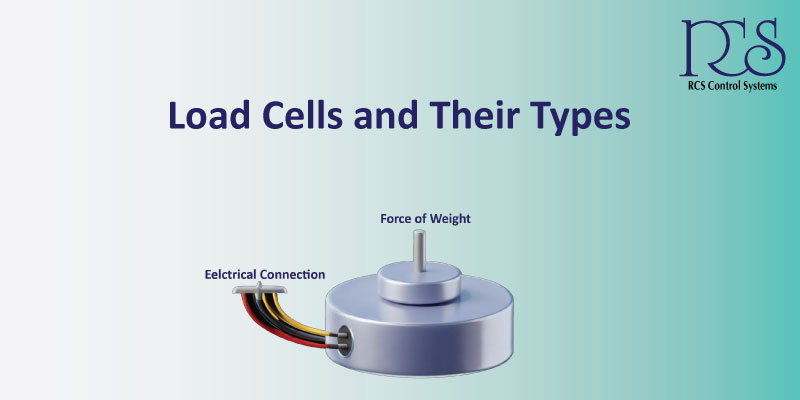

A load cell is a transducer that converts mechanical force (weight) into a measurable electrical signal. This seemingly simple device underpins the functionality of countless weighing applications, from delicate laboratory scales to colossal industrial weighbridges.

To truly understand the power of load cells, visit loadcell.ae, your comprehensive resource for all things weighing. Explore our range of high-quality load cells, delve into technical specifications, and discover how these versatile sensors can transform your operations.

The Science Behind Load Cells: How They Work

Load cells typically employ strain gauge technology. When a force is applied, the load cell deforms slightly, causing a change in resistance within the strain gauges. This change is converted into an electrical signal, which is then amplified and processed to provide an accurate weight reading.

To learn more about the intricate workings of load cells, visit loadcell.ae. Our detailed explanations and informative resources will help you grasp the science behind this essential technology.

Unlocking Precision: Types of Load Cells

Load cells come in various configurations, each designed to excel in specific applications. At loadcell.ae, we offer a diverse range to cater to your unique needs:

- Single Point Load Cells: Ideal for bench scales, force measurement, and basic weighing applications. Compact and easy to install, they provide reliable performance in various settings.

- Tension Load Cells: Specifically designed to measure pulling forces, these load cells are essential for applications like cable tension monitoring, overhead lifting systems, and conveyor belt tension control.

- Compression Load Cells: Built to handle compressive forces, these load cells are widely used in weighbridges, material testing, and hydraulic systems. They are known for their robustness and high load capacity.

- Shear Beam Load Cells: Offering high accuracy and fast response times, shear beam load cells are commonly used in platform scales, tank weighing, and force monitoring.

- Double-Ended Beam Load Cells: Designed for heavy-duty applications, these load cells provide exceptional stability and load capacity. They are ideal for weighbridges, hopper weighing, and industrial process control.

Explore the full range of load cell types on loadcell.ae to find the perfect match for your application.

Building a Robust Weighing System: Essential Components

While load cells are the core component, a complete weighing system requires additional elements:

- Load Cell Accessories: Enhance performance and longevity with mounting hardware, junction boxes, protective covers, and cable assemblies. Loadcell.ae offers a range of accessories to suit your specific needs.

- Controllers: The brain of the system, processing signals, performing calculations, and controlling other components. Advanced controllers can handle complex weighing tasks, integrate with other systems, and provide data management capabilities.

- Weighing Indicators: Display weight readings, provide user interface, and offer additional features like data logging, communication capabilities, and remote access. Loadcell.ae offers a variety of weighing indicators to suit different applications.

- Transmitters: Convert analog signals into digital for remote monitoring, data acquisition, and integration with other systems. Choose from a range of transmitters with different communication protocols and output options.

Loadcell.ae offers a range of accessories and complementary products to build a complete and efficient weighing system.

Selecting the Ideal Load Cell: Key Considerations

Choosing the right load cell involves careful consideration of several factors:

- Application: Clearly define the intended use of the load cell.

- Capacity: Determine the maximum weight the load cell must handle with sufficient overload protection.

- Accuracy: Specify the required level of precision to meet application requirements.

- Environmental Conditions: Consider factors like temperature, humidity, vibration, and potential exposure to harsh environments.

- Output Signal: Select the appropriate output signal (analog or digital) to match your weighing system’s components.

- Mounting Options: Evaluate available mounting configurations based on your application and installation requirements.

- Material Compatibility: Ensure the load cell material is compatible with the substances it will come into contact with.

Loadcell.ae provides detailed product information and expert guidance to help you make informed decisions.

The Power of Load Cells: Transforming Industries

Load cells have revolutionized industries worldwide:

- Manufacturing: Precise weighing for raw materials, finished products, quality control, process optimization, and inventory management.

- Logistics and Transportation: Accurate weight measurement for efficient load distribution, freight optimization, compliance, and safety.

- Food and Beverage: Ensuring product quality, portion control, compliance with regulations, and traceability.

- Pharmaceutical: Maintaining precise measurements for formulation, dosage accuracy, quality control, and compliance with regulatory standards.

- Construction: Accurate weight measurement for materials, load monitoring, safety, and equipment efficiency.

- Agriculture: Efficiently managing inventory, livestock, crop yields, and production processes.

Discover how load cells can transform your industry by visiting loadcell.ae.

Beyond the Basics: Advanced Load Cell Applications

Load cells are not limited to basic weighing tasks. They are integral to advanced applications such as:

- Force Measurement: Measuring tension, compression, and other forces in various industrial processes.

- Dynamic Weighing: Weighing objects in motion, such as conveyor belts, hoppers, and filling machines.

- Load Monitoring: Monitoring loads on structures and equipment for safety, maintenance, and performance optimization.

- Process Control: Integrating load cells into automated systems for precise control of materials and processes.

- Research and Development: Supporting scientific research and product development through accurate force measurement.

Loadcell.ae offers a range of products and solutions to support these advanced applications.

Load Cell Calibration and Maintenance: Ensuring Accuracy

Regular calibration and maintenance are essential for maintaining load cell accuracy and reliability. Loadcell.ae offers calibration services and provides guidelines for proper load cell care.

The Future of Weighing: Advancements in Load Cell Technology

The world of load cells is constantly evolving. Advancements in technology are leading to new and improved load cell designs, materials, and capabilities. Stay updated on the latest trends and innovations by visiting loadcell.ae.

Loadcell.ae is your trusted partner in achieving accurate and reliable weighing solutions. Explore our range of products, gain valuable insights, and elevate your operations.

Contact us today to discuss your specific needs.