Supmeter BST106-F11

Weighing & Totalizing Controller

Supmeter BST106-F11 Introduction

Supmeter BST106-F11 Weighing & Totalizing Controller

Looking for a high-precision weighing and totalizing controller for industrial applications? The Supmeter BST106-F11 is a powerful and reliable solution designed for accurate weight display, real-time alarm outputs, and automatic totalizing. With its high-speed processing, advanced filtering, and seamless connectivity, this controller ensures stable and efficient performance in various weighing systems.

Key Features:

- High Accuracy: With an accuracy grade of III and static weighing accuracy of 0.2%~0.5%, the F11 guarantees precise measurements for industrial weighing applications.

- Advanced Technology: Powered by a 32-bit ARM CPU with a 72MHz clock, delivering high-speed arithmetic processing for real-time weight monitoring.

- Anti-Vibration & Filtering: The 400Hz high-frequency sampling and special anti-vibration digital filtering algorithm ensure stable weight readings and rapid response times.

- User-Friendly Display: Features a 6+10 Green VFD digital tube display, providing clear and easy-to-read weight values and process status.

- Versatile Control Options:

- Weight Limit DO Alarm Mode for real-time alerts.

- Weight Increment & Decrement DO Output Modes for precise material control.

- Weight Section DO Output Mode for batch weighing operations.

- Auto Zero Tracking, Load Calibration, Data Calibration, and Segmenting Correction for long-term accuracy.

- Printing & Reporting: Supports weighing record storage and totalizing report printing, allowing for easy tracking and documentation.

- Robust & Reliable: Designed for industrial environments, featuring a high anti-jam EMC design and an IP65-rated front panel for protection against dust and moisture.

Ideal Applications:

- Hopper Scales: Ensures precise material handling and automated weight totalizing.

- Weight Totalizing Scales: Ideal for industrial applications requiring real-time weight monitoring and automated reporting.

- Industrial Weighing Systems: Used in manufacturing, logistics, and batching processes that require precise weight management.

Technical Highlights:

- Power Supply: AC85~264V, 50/60Hz, Max. 10W.

- Loadcell Support: Connects up to 8 load cells (350Ω) with DC10V excitation voltage.

- Inputs & Outputs:

- 3 Normally Open Switch Inputs (DI) for flexible control.

- 5 Normally Open Relay Outputs (DO) (AC250V/DC24V, 1A).

- 1 Analog Signal Output (AO) (4~20mA, 0.05%FS).

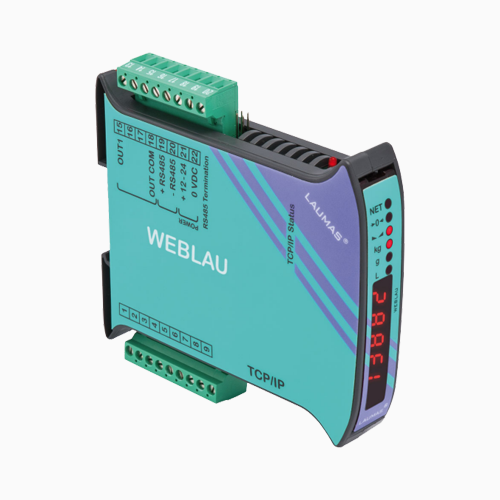

- Connectivity:

- COM1: Fixed RS232 & RS485 (one can be used at a time).

- COM2: Optional RS232/RS485/RS422/Profibus-DP/Ethernet for seamless integration with industrial networks.

- Supports connection to host IPCs, remote displays, printers, and wireless modules.

- Operating Temperature: Built for harsh conditions, with a range of -25℃ to +45℃.

Upgrade Your Weighing System Today!

The Supmeter BST106-F11 is the ideal choice for weighing and totalizing applications, providing high accuracy, intelligent control, and industrial-grade durability. Whether for hopper scales, weight totalizing systems, or industrial weighing processes, this controller ensures smooth and reliable operation.

Contact Loadcell.ae today to learn more about the Supmeter BST106-F11 and optimize your industrial weighing process with cutting-edge technology!

| Brand |

Supmeter |

|---|---|

| Power Supply |

AC85 ~264V |

| Serial ports |

Ethernet ,Profibus-DP ,RS232 ,RS422 ,RS485 |

| Working temperature |

-25 ~ +45 |

| Accuracy Grade |

III |

Downloads

Related products

Laumas W100

د.إ0

Laumas W200

د.إ0

Laumas WINOX-G

د.إ0

Reviews

There are no reviews yet.